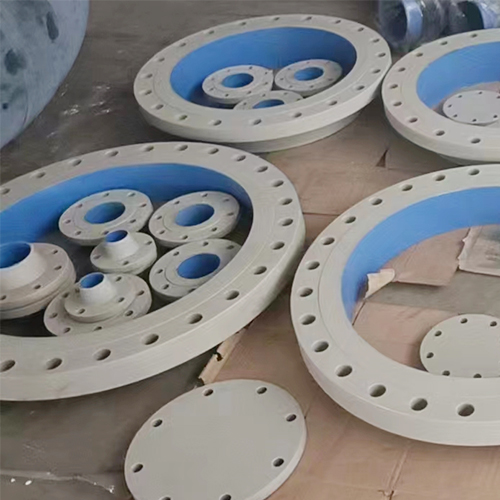

Carbon Steel/Stainless Steel Socket Weld Flanges

We have collaborated with numerous clients in various industries, providing them with reliable and efficient socket weld flanges that meet their specific requirements. With our state-of-the-art manufacturing facilities, we have the ability to produce socket weld flanges in large quantities, ensuring timely delivery to meet customer demands.

Carbon steel socket weld pipe flanges are a type of flange that is designed to be welded directly onto the pipe. They provide a strong and leak-proof connection, making them suitable for high-pressure and high-temperature applications, like oil and gas pipelines, refineries, and offshore platforms, where high-pressure and leak-free connections are crucial.

Type | ASTM/ANSI Standard Carbon Steel Pipe Fitting Pipe Flange |

Pressure | Class150/300/600/9001500/2500 |

Process | Forging |

Standard | ASTM A/SA-105, ANSI B16.5 |

Size | 15-6000mm |

Wall Thickness | SCH5S/10S, SCH20/40/80/160, STD/XS/XXS, etc. |

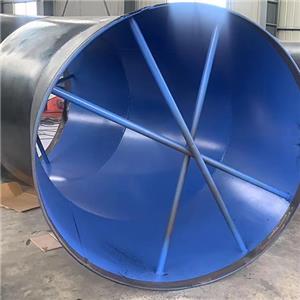

Surface | Black paint, varnish, galvanized, sand blast, 3PE |

Test | Chemical Component Analysis, Mechanical Properties, Technical Properties, Outer Diameter/Thickness/Hole Diameter/Hole Distance Inspection, Hydraulic Testing , X-ray Testing |

Packaging | Plywood\wooden pallets, or as your requirements |

Features and applications of carbon steel socket weld pipe flanges:

1. Welded connection: providing a strong and reliable connection that is resistant to leakage.

2. High-pressure capability: These flanges are designed to withstand high-pressure applications, making them suitable for industries such as oil and gas, petrochemical, and power generation.

3. Compact design: Socket weld flanges have a compact design, making them ideal for piping systems with limited space or where frequent disassembly is not required.

4. Enhanced flow characteristics: The smooth transition from the pipe to the flange helps to minimize turbulence and pressure drop in the system, improving flow characteristics.