- Home

- >

- Products

- >

- Stainless Steel Seamless Pipe

- >

- Chemical Industry TP321 Stainless Steel Seamless Pipe

Chemical Industry TP321 Stainless Steel Seamless Pipe

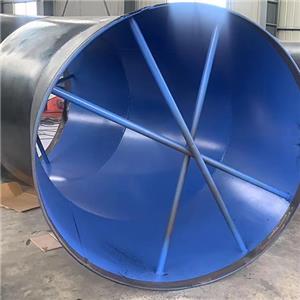

TP321 stainless steel seamless pipe stands out for its exceptional corrosion resistance, high-temperature strength, weldability, and resistance to intergranular corrosion, making it a preferred choice for fluid transmission pipelines.

TP321 stainless steel seamless pipe, specifically designed for high temperature environments.

Firstly, TP321 seamless steel pipe exhibits excellent corrosion resistance to a wide range of corrosive environments, including high-temperature and acidic conditions. This makes TP321 ideal for applications where corrosion resistance is crucial. Secondly, TP321 has superior high-temperature strength, allowing TP321 pipe to withstand elevated temperatures without compromising its structural integrity. This makes TP321 pipe suitable for high-temperature fluid transportation.

Type: Seamless Stainless Steel Pipe

Grade: ASTM TP304/TP304L/TP304H, TP316/TP316L/TP316H, TP321, TP405, TP430, etc.

ASTM A213/SA213, ASTM A312/SA312, ASTM A789 | |||

Austenitic | Ferritic & Martensitic | Ferritic / Austenitic | |

TP 304 | TP 316H | TP 405 | S32900 |

TP 304L | TP 316Ti | TP 410 | S31803 |

TP 304H | TP 321 | TP 430 | S32205 |

TP 310S | TP 312H | S32750 | |

TP 310H | TP 347 | S31500 | |

TP 316 | TP 347H | ||

TP 316L | |||

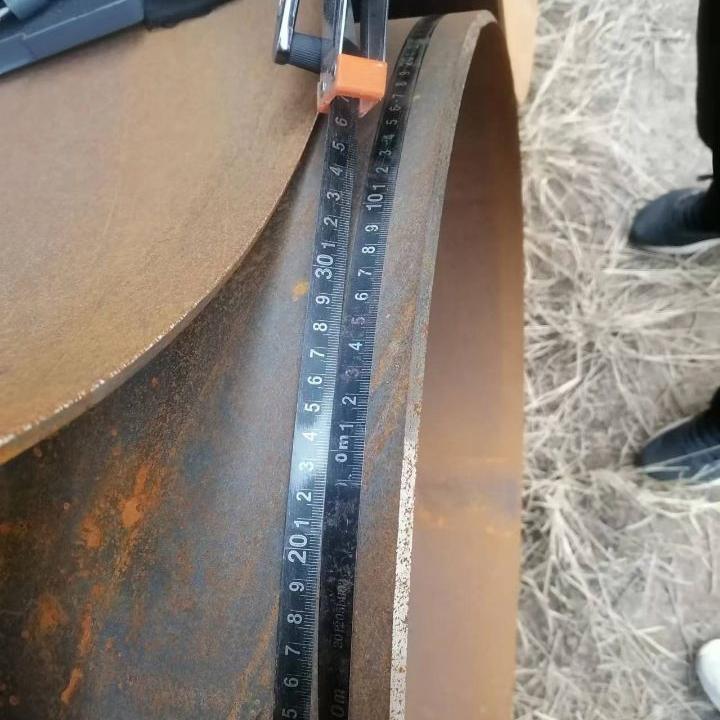

Wall Thickness: 1-5mm

Stainless Steel Seamless Round Pipes Parameters Chart:

| Dimension | 10 SWG(3.2MM) | 12 SWG(2.6MM) | 14 SWG(2.1MM) | 16 SWG(1.65MM) | 18 SWG (1.2MM) | 19 SWG(1.0MM) | |||

Size | OD | Weight/MTR | Weight/MTR | Weight/MTR | Weight/MTR | Weight/MTR | Weight/MTR | ||

1/2" | 12.7 | 0.754 | 0.651 | 0.552 | 0.452 | 0.342 | 0.290 | ||

5/8" | 15.875 | 1.006 | 0.856 | 0.718 | 0.582 | 0.437 | 0.369 | ||

3/4" | 19.05 | 1.258 | 1.061 | 0.883 | 0.712 | 0.531 | 0.448 | ||

1" | 25.4 | 1.762 | 1.470 | 1.214 | 0.972 | 0.720 | 0.605 | ||

1 1/4" | 31.75 | 2.266 | 1.880 | 1.544 | 1.232 | 0.909 | 0.763 | ||

1 1/2" | 38.1 | 2.770 | 2.289 | 1.875 | 1.492 | 1.098 | 0.920 | ||

2" | 50.8 | 3.778 | 3.108 | 2.537 | 2.012 | 1.476 | 1.235 | ||

2 1/2" | 63.5 | 4.786 | 3.928 | 3.198 | 2.531 | 1.854 | 1.550 | ||

3" | 76.2 | 5.794 | 4.747 | 3.860 | 3.051 | 2.232 | 1.865 | ||

3 1/2" | 88.9 | 6.802 | 5.566 | 4.521 | 3.571 | 2.610 | 2.180 | ||

4" | 101.6 | 7.810 | 6.385 | 5.183 | 4.091 | 2.988 | 2.495 | ||

Production Process: Hot Rolled

Features: High strength, corrosion resistance, high temperature resistance

Scope of application: marine, environmental protection, energy, petrochemical field, etc.

Factory Advantage: Complete specifications, QC inspection of steel pipes, can be deep processing

Delivery Time: 15-20 Days